HAWKE Transit System at Data Centre World 2024: Leading the Charge in Data Security

HAWKE Transit System proudly announces its presence at Data Centre World 2024, currently underway at the ExCeL Exhibition Centre in London. Amidst a vibrant atmosphere brimming with industry stakeholders, our team is stationed at booth D480, ready to engage with attendees and discuss the future of data security. Data Centre World 2024 has proven to be a resounding success, attracting a diverse array of participants from across the data center sector. With enthusiastic engagement from all stakeholders, the event serves as a testament to the industry’s collective commitment to innovation and progress. At HAWKE Transit System, we are excited to showcase our innovative HAWKE MCT Sealing System, designed to elevate data protection standards within data centers. Our solutions are tailored to address the evolving challenges of data security, ensuring the integrity and safety of critical infrastructures. We extend a warm invitation to all attendees to visit our booth and discover our innovative HAWKE MCT Sealing Systems. We are eager to showcase our solutions and listen to your needs and inquiries. Whether you’re looking to enhance data center security or require customized solutions tailored to your specific requirements, our team is here to assist you every step of the way. As we reflect on our commitment to driving excellence and innovation in the data center industry, we are thrilled to be a part of Data Centre World 2024. Together, let’s shape the future of data security and forge new pathways for success. For more information about our presence at Data Centre World 2024 and our cutting-edge sealing solutions, visit Hawke HTS | Hawke MCT Sealing Solutions (hts-mct.com) We eagerly anticipate your visit!

HAWKE Transit System’s Presence at Data Centre World 2024 in London

HAWKE Transit System, a global leader in MCT sealing solutions for critical infrastructure, is gearing up to make its mark at Data Centre World 2024, scheduled to take place in London on March 6-7, 2024. You can find us at booth D480. Data Centre World is a premier event that brings together industry leaders to explore and showcase the latest advancements in data centre technologies and strategies. Hosted by renowned organizations in the field, Data Centre World serves as a pivotal platform for innovation and collaboration, driving progress in critical areas such as data storage, cybersecurity, cloud computing, and AI integration. HAWKE Transit System is dedicated to addressing the evolving needs of data centres and actively seeks out innovative solutions to enhance data security and integrity. MCT HAWKE Sealing Systems – Ensuring Data Protection At the core of HAWKE Transit System’s offerings are the MCT HAWKE sealing systems, indispensable for maintaining data security in critical infrastructures. These systems safeguard assets in various environments, including data centres, telecommunications facilities, and projects related to digital transformation and IoT integration. Customized Solutions The engineers at HAWKE Transit System specialize in providing tailored solutions, ensuring robust sealing systems and personalized assistance tailored to the specific requirements of each data centre project. Looking ahead to our participation in Data Centre World 2024, HAWKE Transit System remains committed to aligning with the event’s objectives and contributing to transformative advancements in the data centre industry. We cordially invite you to visit us at our booth D480 to learn more about our sealing solutions and our dedication to innovation!

Completado con éxito el suministro para el Proyecto Qatargas North Field Expansion

Hawke Transit System marca un hito significativo al completar con éxito el suministro para el ambicioso proyecto Qatargas North Field Expansion Project. Una colaboración exitosa con Saipem, líder en servicios de ingeniería y construcción con sede en Milán, Italia. El proyecto, diseñado para incrementar la extracción de gas natural del Campo Norte, ubicado frente a la costa noreste de la península de Qatar, se ha llevado a cabo con éxito y en concordancia con los estándares de calidad más rigurosos. Gestionado para nuestro cliente Saipem, esta iniciativa refuerza la posición de Hawke Transit System como líder en la industria y demuestra nuestra habilidad para superar expectativas en proyectos de escala global. Felicitamos con entusiasmo a todo el equipo de Hawke Transit System por su dedicación y excelencia en la ejecución de este proyecto. Este logro no solo refleja nuestro compromiso continuo con la calidad y la innovación, sino que también fortalece nuestra posición como referentes en la industria.

The reason for the need for modular sealing systems for cables and pipes in Data Centers

Sealing solutions for DPCs

The advantages of being present in all phases of the product life cycle

The presence of a company throughout the entire life cycle of the product, from the first phase of design, production and distribution, to the installation and inspection phase, is a determining factor that implies better quality management and better customer service. Businesses depend on their customers and therefore should understand current and future customer needs, meet customer requirements, and strive to exceed customer expectations. In this sense, being present throughout the product and service process helps to understand these needs and to go one step ahead to meet the demands of the most demanding customers. At Hawke Transit System we are present throughout the process of both product and service. This allows us to perfectly monitor the different phases, establishing the necessary synergies between the different departments and with our clients, in search of excellence. Being present throughout the product and service process helps to understand customer needs and to go one step ahead to meet the demands of the most demanding customers. Controlling design, production and distribution requires continuous listening to our customers, their demands and expectations, which means maintaining a close relationship of trust with them, which is specified in the continuous updating of our processes. The presence in the service phase, both in the installation and in the inspection processes, achieves a zero error range in our facilities, extends the life cycle of our product and effectively meets the demands of our customers. This process control is undoubtedly reflected in the quality of our products and in the trust that our customers place in us.

Hawke Transit System sealing solutions for the wind energy industry

A practical and effective solution in the most extreme conditions Over recent years we have seen how our mountains, our valleys, our seas were filled with wind turbines. The wind energy industry has not stopped growing and the high energy demand of today’s society predicts that it will continue to grow in the coming decades. These wind farms, both onshore and offshore, are exposed to multiple risks, to extreme weather conditions in many cases. The need for a reliable cable transit system that is quick and easy to install and inspect is self-evident. Hawke sealing system is well known among wind energy players, installers, engineers for its unrivaled quality, easy installation, flexibility and inspectability and for not generating waste that could pose a risk to the installation. In extreme conditions, these features make a vital difference to other modular cable and pipe sealing systems. Hawke offers sealing solutions for any type of wind energy project, perfectly adapting to the needs of the project. Sealing solutions for offshore wind farms, onshore farms and for Wind turbines that protect installations in severe environmental conditions against fire, gas leaks, water pressure or corrosion. The wind industry has in the Hawke Transit System a partner they can trust for the many future projects that lie ahead. Over the years, Hawke Transit System sealing solutions have been chosen for large-scale projects such as, among others, Wikinger, Iberdrola’s first wind farm in the Baltic Sea. Opened in 2018, this offshore wind farm supplies renewable and highly efficient energy to 350,000 German homes. A large-scale project that has relied on Hawke’s modular systems for sealing cables and pipes. The wind industry has in the Hawke Transit System a partner they can trust for the many future projects that lie ahead. Click here for more information on Wikinger project.

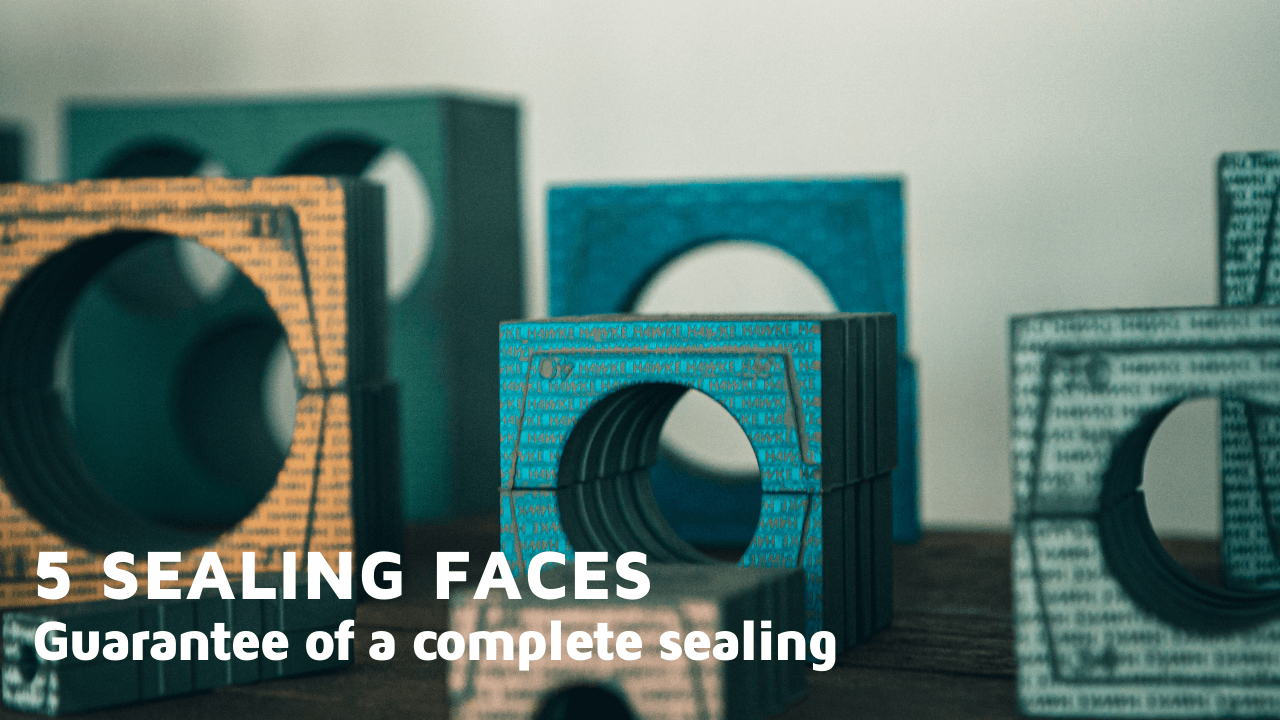

The 5 sealing faces of the Hawke Transit System blocks

A characteristic attribute that guarantees the complete sealing of a cable or pipe We spoke with Antonio Alonso, HTS Product Manager, about this unique feature that we find in the Hawke Transit System sealing blocks. Hello Antonio. Could you tell us what is the function of the so-called 5 sealing faces? The 5 sealing faces function as 5 differentiated sealing points within the compression system where the block grips the cable. This structure of the blocks provides a great adaptability of these to the different cables or pipes and gives our system a lot of flexibility when choosing the blocks for sealing a certain cable or pipe. How do they act? These 5 sealing faces act in two ways. 1º In the event of a possible leakage of fluid elements such as water or gas, each time these elements face one of these sealing faces, they make it difficult for them to pass through. 2º They adapt perfectly to the shape of the cable or pipe. The grooves inside the block allow the 5 sealing faces to deform as necessary to adapt to all the irregularities that the cable or pipe may present, since as we know many cables and pipes do not come perfectly smooth. This structure of the blocks provides a great adaptability of these to the different cables or pipes and gives our system a lot of flexibility Do they guarantee total tightness? Absolutely. Our blocks guarantee the total tightness of the passage. What material are these blocks made of and why? These blocks are made of a type of intumescent polymer, free of halogens, which in case of fire guarantees their integrity and the safety of all personnel who are in a close radius. This composition prevents them from releasing toxic fumes that are potentially harmful to health. In summary, our blocks have a structure and composition governed by the highest quality standards and guarantee the total tightness of the transit, protecting both the assets of our clients and the lives of the personnel.

Inspectionability; a basic aspect when choosing a sealing system for cables and pipes

Hawke Transit System makes it easy to inspect MCT systems by color-coding their blocks It is common to find cable entry installations in spaces that are difficult to access or with little lighting, which in many cases make it extremely difficult not only for the installation but also for the subsequent inspection of that installation or its modification if necessary. For this reason it is vitally important that the chosen sealing system facilitates its inspectability. Faced with an extreme situation, an installation error can have terrible consequences for the occupants of the space in question and for the entire construction. With this in mind, Hawke Transit System developed a color-coding system that made it easier for the installer to verify that the installation had been done correctly. In this system each individual plug has a color-coded face, which ensures that each size and pair of halves of each block always correctly match the diameter of the cable. This color coding allows the inspector to identify without the possibility of error that the blocks have been correctly dimensioned for each wire size. As we can see in the image, an installation with all the plugs of the same color sealing different cable diameters, makes it very difficult to inspect and can easily generate installation errors. While the use of color-coded plugs greatly facilitates inspection and avoids installation errors. After different tests, at Hawke Transit System we are clear that the use of color-coded blocks limits installation errors to practically zero and facilitates the installer’s work, saving him a lot of time and effort.