Inspectionability; a basic aspect when choosing a sealing system for cables and pipes

Hawke Transit System makes it easy to inspect MCT systems by color-coding their blocks It is common to find cable entry installations in spaces that are difficult to access or with little lighting, which in many cases make it extremely difficult not only for the installation but also for the subsequent inspection of that installation […]

The 5 sealing faces of the Hawke Transit System blocks

A characteristic attribute that guarantees the complete sealing of a cable or pipe We spoke with Antonio Alonso, HTS Product Manager, about this unique feature that we find in the Hawke Transit System sealing blocks. Hello Antonio. Could you tell us what is the function of the so-called 5 sealing faces? The 5 sealing faces […]

Hawke Transit System sealing solutions for the wind energy industry

A practical and effective solution in the most extreme conditions Over recent years we have seen how our mountains, our valleys, our seas were filled with wind turbines. The wind energy industry has not stopped growing and the high energy demand of today’s society predicts that it will continue to grow in the coming decades. […]

The advantages of being present in all phases of the product life cycle

The presence of a company throughout the entire life cycle of the product, from the first phase of design, production and distribution, to the installation and inspection phase, is a determining factor that implies better quality management and better customer service. Businesses depend on their customers and therefore should understand current and future customer needs, […]

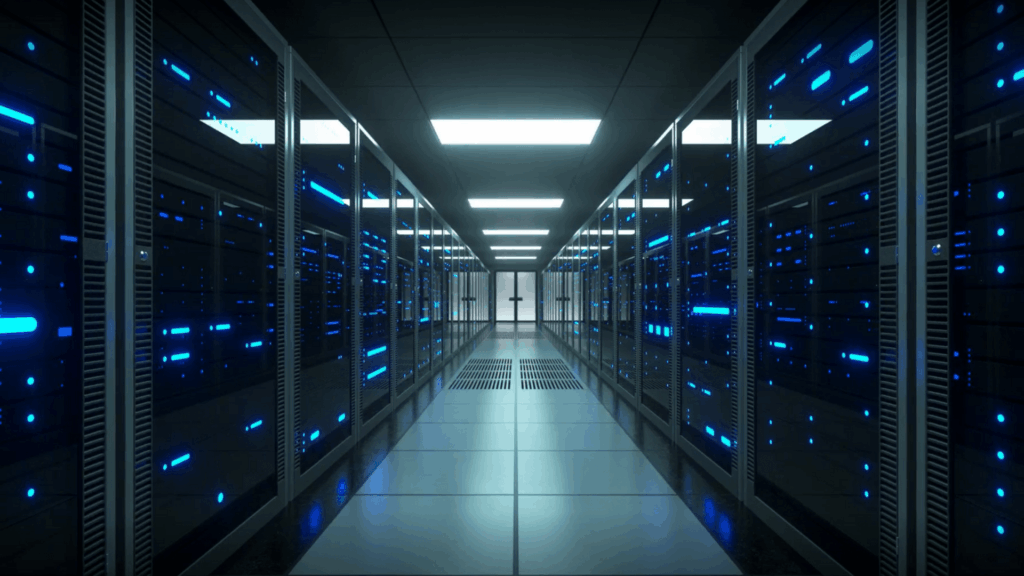

The reason for the need for modular sealing systems for cables and pipes in Data Centers

Sealing solutions for DPCs

Cable and Pipe Seals for Royal Australian Navy AOR Ships

Hawke Transit System cables and pipes installed seals offer protection against multiple hazards, including EMP, EMI and resistance to detonating charges. The Supply-class ships, Auxiliary Oiler Replenishment (AOR), are two new ships built by the Spanish company Navantia for the Royal Australian Navy. The ships have been designed for different functions such as supplying dry […]

Reasons to choose Hawke Transit System products for cable and pipe sealing

During the sealing of cables or pipes in an installation, there are many problems that you may face if you do not choose a good quality product. To prevent this, Hawke Transit System products guarantee the highest level of performance in cable and pipe sealing. Among its many qualities it is worth highlighting: Maximum safety […]

We began this year 2023 by being involved in new projects, among which hydrogen plants stand out

We began this year 2023 by being involved in new projects, among which hydrogen plants stand out. Due to the flammability of this gas, our HAWKE sealing systems become the safest option for fire protection in cable and pipe penetration (MCT). In addition, our products provide all the security and suitable sealing solutions for green […]

Successfully completed the supply for the Qatargas North Field Expansion Project.

Hawke Transit System has reached a significant milestone by successfully completing the supply scope for the ambitious Qatargas North Field Expansion Project—an accomplishment achieved in partnership with Saipem, the Milan‑based leader in engineering and construction services. The project, aimed at increasing natural‑gas extraction from the North Field off the northeast coast of Qatar’s peninsula, was executed successfully and in full […]

Hawke Transit System Signs Contract with Saudi Aramco and Larsen & Toubro for the Hydrocarbon CRPO Project

Hawke Transit System (HTS) has reached a major milestone by signing a strategic contract with Larsen & Toubro, one of the world’s leading engineering, procurement and construction (EPC) companies, to supply sealing systems for Saudi Aramco’s Hydrocarbon CRPO 117‑119 & 120 project. Saudi Arabia’s offshore hydrocarbon resources—spanning key fields such as Abu Safah, Arabiyah, Hasbah, Berri, Karan, Manifa, Marjan, Ribyan, Safaniya and Zuluf—form the backbone […]