Industrial safety in high-risk gas processing facilities

HTS supports critical infrastructure in a demanding environment The Riyas NGL – NGL Fractionation Project, led by Saudi Aramco, aims to increase natural gas liquids (NGL) processing capacity in one of Saudi Arabia’s most active industrial zones. This is a highly technical facility handling large volumes of pressurized gases, dense electrical systems, and subject to […]

Reliable sealing systems for offshore production units

HTS contributes to the most ambitious standardized FPSO program on the market The Fast4Ward FPSO Program, developed by SBM Offshore, aims to revolutionize the delivery of floating production, storage, and offloading units (FPSOs). By applying a standardized approach, the program accelerates deployment, reduces engineering time, and lowers risk across major offshore energy projects. Within this […]

Certified sealing systems for one of the world’s largest LNG developments

HTS supports infrastructure safety in Qatar’s strategic gas expansion project The North Field Expansion (NFE) project, led by QatarEnergy, is one of the largest developments in the history of liquefied natural gas (LNG). Its goal is to significantly increase the country’s production capacity, strengthening Qatar’s position as a global leader in LNG exports. Within this […]

Reliable sealing systems for complex industrial environments

HTS delivers certified solutions for one of the Gulf region’s most demanding energy programs The Hydrocarbon CRPO Program by Saudi Aramco is one of the most important infrastructure initiatives supporting the energy sector in the Gulf. It includes a series of high-impact projects aimed at expanding, maintaining, and upgrading facilities for the processing and transport […]

Hawke Design Software – Hawke Transit System

Hawke Design Software streamlines and simplifies the design of your cable and pipe transit (MCT) projects by automatically calculating the required bill of materials and its distribution, thus maintaining full traceability of all cable data, area saturation percentages, and more. Thanks to our HDS software, it is possible to import data from an external file, […]

Reaffirming our commitment to sustainability as an unquestionable business practice

A company committed to the future of our planet A few days ago we saw the closing of the UN Climate Change Conference in Glasgow. Conference in which all the commitments that we would have liked have not been reached, but which certainly represents a small advance in that task of all of us that […]

Innovation, talent and entrepreneurship

The Fire Cluster, CIF Cantabria, inaugurates its new facilities on Paseo del Niño in Torrelavega. In the presence of the Regional Minister of Industry, Tourism, Innovation, Transport and Commerce of the Government of Cantabria, Javier López Marcano, and with: “The main objective is to support Cantabrian companies in improving their competitiveness through innovation and internationalisation, and to create a […]

EX Transit System – Hawke Transit System

En el año 2020, Hawke Transit System ha sido beneficiaria de las subvenciones concedidas por el GOBIERNO DE CANTABRIA en relación al FONDO EUROPEO DE DESARROLLO REGIONAL (FEDER) y del FONDO SOCIAL EUROPEO. Desde Hawke agradecemos el apoyo mostrado por las instituciones para fomentar la industria.

We implemented a new cybersecurity system to protect Hawke Transit System effectively against cyberattacks

We shield our systems against possible cyberattacks As a company dedicated to developing sealing systems for cables and pipes that protect the integrity of walls and bulkheads, we are committed to security in general, and to cybersecurity in particular, as one of the most important aspects today to guarantee security of companies. Throughout the last […]

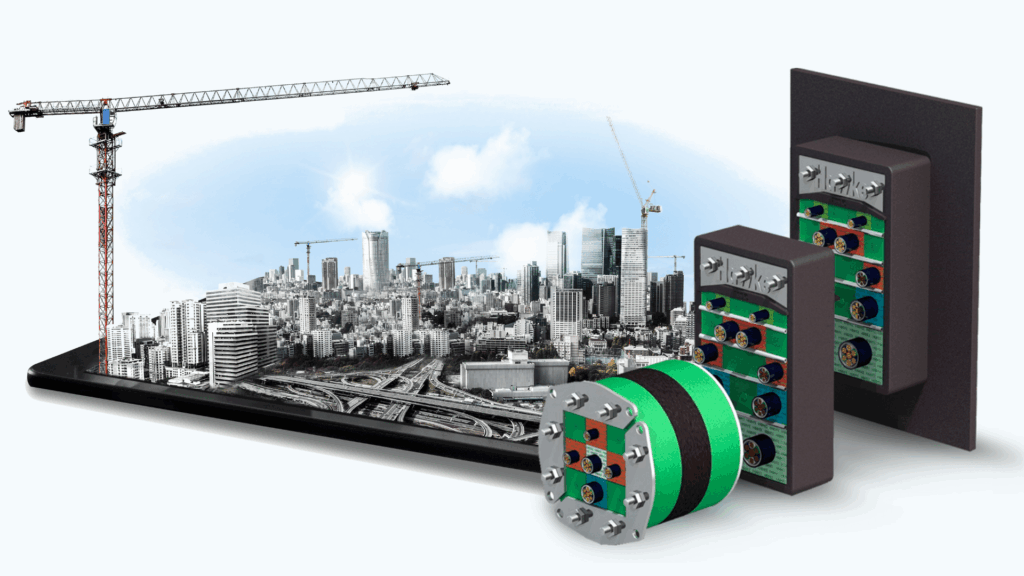

Sealing solutions for cables and pipes; an unavoidable need in new civil construction

Airports, train stations, sports halls, CPDs, shopping centers, hospitals, laboratories … All these buildings have in common the high traffic of people they host, which means that they must meet the highest safety standards. All of them also have their weak point in common; cables and pipes pass through its walls, and those passages, lacking […]